Custom Millwork & Woodworking in Burbank, CA

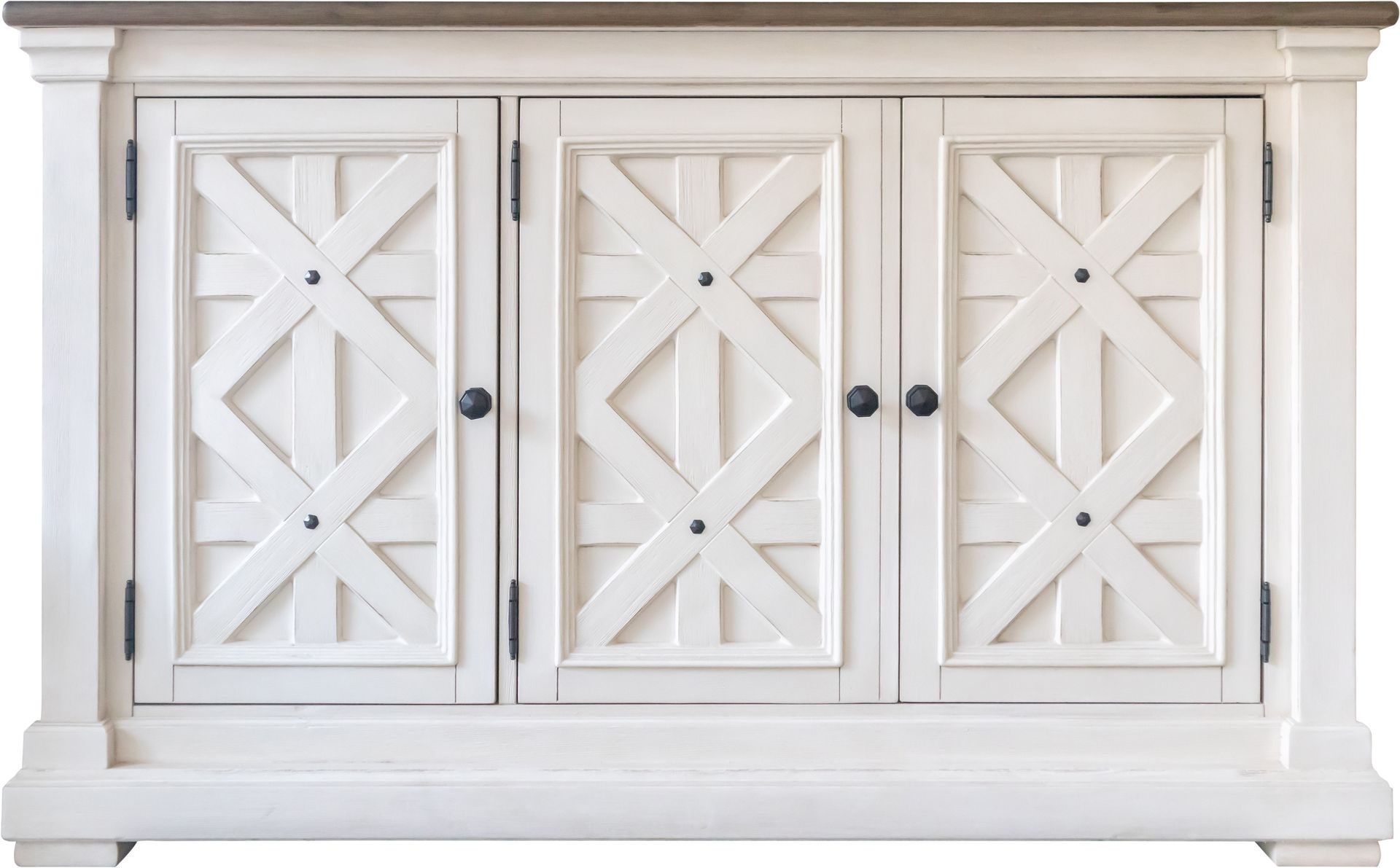

Burbank Custom Cabinets specializes in custom millwork & woodworking for cabinets that combine functionality, durability, and style. According to the National Association of Home Builders (NAHB), custom millwork and cabinetry are among the top features that increase both resale value and buyer appeal in homes. Our expertise in architectural millwork and custom cabinetry millwork ensures every project—whether residential or commercial—delivers storage solutions and cabinets that elevate your space.

From residential millwork and woodworking for cabinets to commercial millwork, we craft built-in millwork, luxury millwork, and custom wood furniture with precision. Using trusted materials and brands such as Blum hardware, Rev-A-Shelf organizers, and premium hardwoods from local Los Angeles suppliers, we create pieces built to last. Serving clients across Burbank, Los Angeles, and the San Fernando Valley, our team works closely with you to maximize space, enhance design, and bring your vision to life.

Our Custom Millwork & Woodworking Services

We specialize in creating tailored woodworking solutions that combine traditional craftsmanship with modern precision using computer numerical control (CNC) machining, shapers, and hand tools. Each project utilizes premium materials like maple, cherry, walnut, and mahogany hardwoods alongside engineered products like medium density fiberboard (MDF) and marine-grade plywood for specific applications.

Our Millwork and Woodworking Expertise

Our work reflects a deep commitment to quality, precision, and detail, ensuring every custom cabinet and storage solution meets exacting standards. We use superior materials, advanced manufacturing techniques, and careful inspection to deliver durable and visually appealing products.

Quality Materials and Finishes

We carefully select hardwoods, plywood, and veneers that balance strength and appearance. Our materials come from trusted suppliers known for consistency and sustainability. For finishes, we apply durable stains, paints, and sealants designed to resist wear and moisture.

Each finish is meticulously applied by hand or state-of-the-art spray systems, avoiding runs or inconsistencies. The result is smooth surfaces with uniform color and texture that enhance both residential and commercial spaces.

Precision Manufacturing Processes

Our cabinet manufacturing process combines modern CNC machining with skilled hand assembly. CNC routers cut components with exact measurements to ensure perfect fit and alignment. This precision minimizes waste and speeds up production without sacrificing quality.

We also employ joinery techniques like dovetail and mortise-and-tenon for strength and durability. Every part passes thorough inspection before assembly, ensuring that only components meeting our standards move forward.

Attention to Detail in Every Project

We focus on the small aspects that distinguish our work. This includes smooth edges, seamless joints, and hardware placement tailored to functionality and aesthetics. Custom features such as soft-close drawers, integrated lighting, and specialized storage compartments are standard.

Throughout each project, our team performs regular quality checks and communicates closely with clients to align with design preferences and practical needs. This approach ensures the final product fits perfectly and performs reliably over time.

Why Choose Burbank Custom Cabinets

We focus on delivering high-quality craftsmanship combined with transparent communication and on-time project delivery. Our commitment is to make the custom millwork process smooth and dependable for both residential and commercial clients.

Reputation for Professionalism

We prioritize professionalism in every interaction. Our team consists of skilled craftsmen with years of experience in custom cabinetry and woodworking. We ensure every project meets client specifications precisely without shortcuts. We maintain consistent quality control throughout each phase, from initial design to final installation. Our reputation is built on clear agreements, respect for your space, and a clean work environment.

Timely Project

Completion

Meeting deadlines is essential in custom woodworking, especially for businesses and busy households. We develop realistic project timelines and stick to them with no unnecessary delays. Our scheduling accounts for all stages, including material sourcing, crafting, and finishing. To prevent overruns, we closely monitor progress and adjust resources as needed. If unavoidable changes arise, we communicate immediately and propose solutions.

Reliable Customer Communication

Clear, ongoing communication is key in custom cabinetry. We provide regular updates throughout the project to keep you informed of progress and any adjustments. Our team is available to answer questions promptly, ensuring there are no surprises. We use detailed consultations and written documentation to confirm project details before work begins. This transparency helps align expectations with results.

Frequently Asked Questions About Custom Millwork & Woodworking

How much does custom millwork cost?

Custom millwork costs $15 to $150 per linear foot depending on complexity and wood species. Burbank Custom Cabinets charges $15 to $25 per linear foot for simple baseboards or casings, while elaborate crown molding or fireplace mantels range $75 to $150 per linear foot. Factors include wood selection like pine versus walnut, hand-carved details, curved profiles, and installation complexity.

What's the difference between millwork and carpentry?

Millwork refers to finished wood products manufactured in a shop environment including trim, molding, and built-ins requiring precision machining. Carpentry encompasses broader construction work including framing and rough structural work. Burbank Custom Cabinets specializes in finish millwork using CNC machines and hand tools for architectural details, while general carpenters handle structural construction.

Can you create custom trim and molding?

Yes, we create custom trim and molding profiles tailored to your architectural style including crown molding, baseboards, chair rails, and window casings. We work with wood species like pine, oak, maple, cherry, and mahogany using CNC routing, shaper cutters, and traditional hand tools. Installation includes proper joinery techniques like coped joints and scribed fits for professional results.

What types of custom woodwork do you offer?

Burbank Custom Cabinets offers built-in bookcases, entertainment centers, window seats, fireplace mantels, wainscoting, coffered ceilings, and custom furniture. We create architectural elements like stair balusters, corbels, kitchen islands, mudroom benches, wine storage, and home office built-ins. Specialty services include restoration millwork for historic homes requiring period-accurate profiles and traditional joinery methods.

How long does custom millwork take?

Custom millwork projects take 2 to 6 weeks depending on complexity. Simple trim installation requires 3 to 5 days, while elaborate built-ins or coffered ceilings may take 4 to 6 weeks. Timeline factors include wood availability, custom profile development, hand-carving requirements, and finishing processes like staining and protective coating application.